With continuous breakthroughs in strategic fields such as wind power and high-end bearings in my country, the ring rolling mill industry is experiencing a dual boom in technology and market. The ability to master the design, manufacturing, and integration of key components and systems has become crucial to the industry's sustainable upgrading.

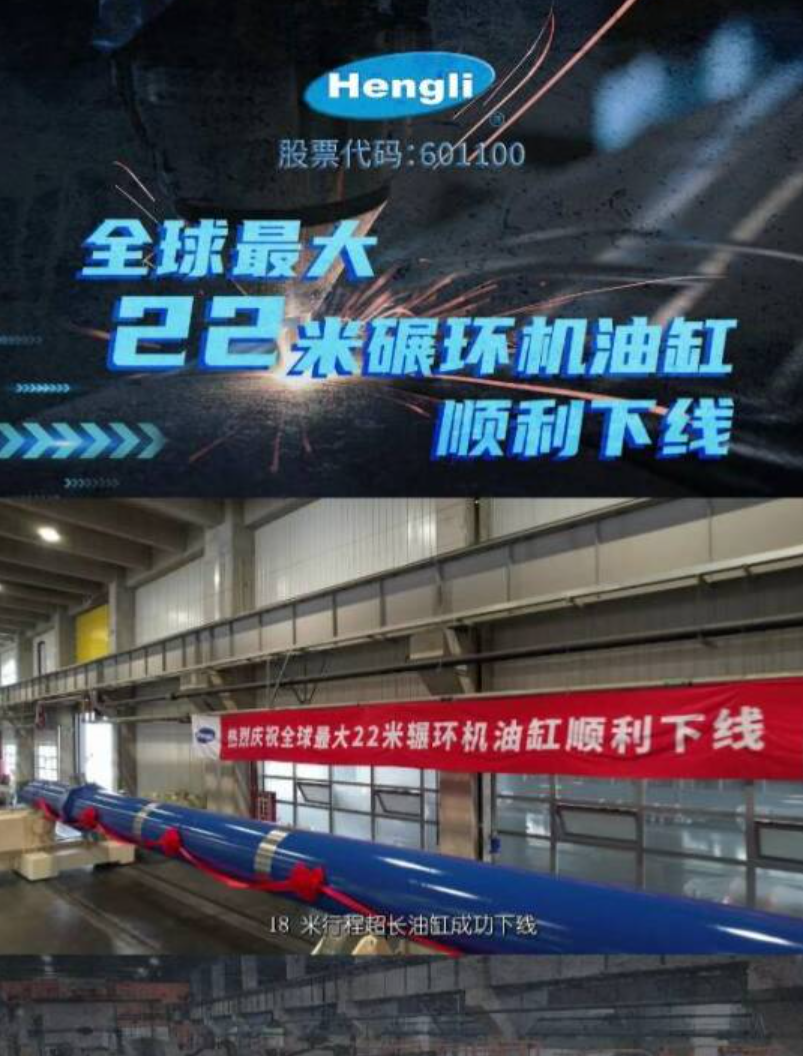

As is well known, the core transmission and control of modern ring rolling mills rely on electro-hydraulic servo proportional systems. Hengli Hydraulics, a leading company in China's electro-hydraulic industry, recently developed customized solutions for two major projects: hydraulic cylinders for the world's largest 22-meter ring rolling mill, and a composite hydraulic cylinder and electro-hydraulic system for a 15-meter ring rolling mill . These two solutions not only deeply meet customer needs but also set a new performance benchmark for electro-hydraulic technology in ring rolling mills.

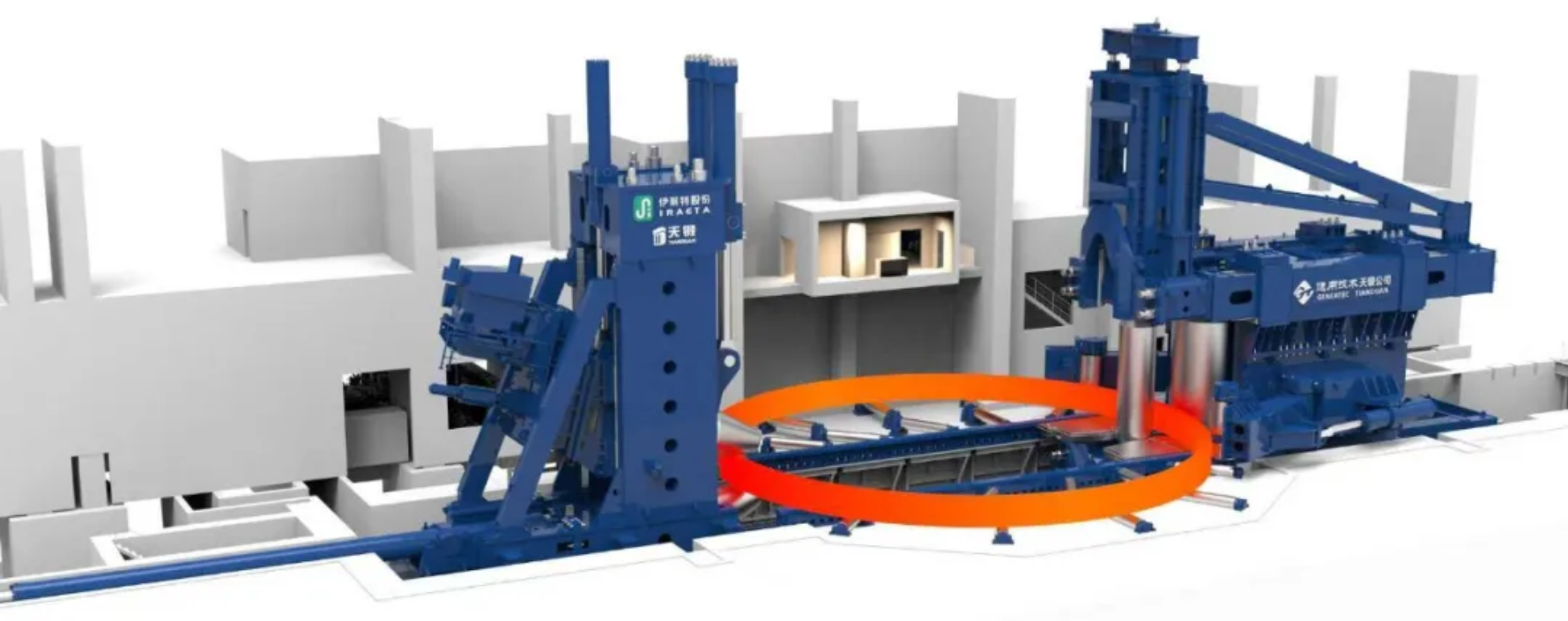

22-meter ring rolling mill

Limiting dimensions, overcoming technical challenges

This hydraulic cylinder, which drives the precision forging of a 22-meter-class ring rolling mill, is not simply a "size enlargement," but a groundbreaking product developed by Hengli Hydraulics based on decades of technological accumulation. Its technological highlights are concentrated in two dimensions:

Profound technological accumulation supports design breakthroughs: From the early days of developing conventional hydraulic cylinders "from scratch," to low-friction cylinders, high-performance cylinders with gap seals, and then to the independent design and manufacturing of servo actuators, Hengli's decades of solid accumulation have laid a solid foundation for the research and development of the 22-meter ultra-large hydraulic cylinder. This success is a practical verification of its technological accumulation.

Innovative Structure Solves Extreme Working Condition Challenges: Facing the extreme working conditions of a 22-meter ring rolling mill with "large stroke and high-frequency reversal," as well as the risk of excessive deflection due to the large cylinder size, Hengli Hydraulics innovatively adopted a "dual-stage buffer + synchronous guidance" structure. This design strictly meets the stringent requirements of high-pressure electro-hydraulic servo systems for micron-level precision and surface quality, perfectly achieving the equipment's extreme performance indicators in dynamic/static position control, synchronization, and operating speed, while ensuring a high degree of balance between operating efficiency and stability.

15-meter ring rolling mill

Intelligent core, full-chain collaboration

In the concurrently progressing 15-meter ring rolling mill project, both the hydraulic cylinders and the integrated system were provided by Hengli . The hydraulic cylinders, in particular, employ a groundbreaking "composite cylinder" architecture . This actuator not only needed to strictly match the customer's precise parameter requirements, but also, due to its unique structure, relied entirely on "simulation calculation + finite element analysis" technology throughout the design phase to ensure structural stability and performance compliance.

As the power core of the entire control system, the integrated system of this project adopts the high-pressure series piston pumps from the German brand InLine, including four F30D520 fixed displacement piston pumps (each with a displacement of 520cc and a rated pressure of 420bar), and two V32G280 and two V32G110 variable displacement piston pumps . It is worth mentioning that the V32G series products are equipped with Hengli Hydraulics' patented "variable displacement control technology," which can match the core parameters of the system in real time according to different working conditions such as "large flow rate in rough forging and high precision in fine forging"—saving over 25% more energy than traditional fixed displacement pump systems, with operating noise ≤75dB, and maintaining a "rock-solid" operating state even in the dusty and vibrating forging workshop.

From customizing a 15-meter dedicated composite cylinder to conquering the world's largest 22-meter ring rolling mill cylinder, and then to delivering a one-stop solution for a complete electro-hydraulic control system—every breakthrough of Hengli Hydraulics is a vivid microcosm of the continuous advancement of China's industrial manufacturing.

If the 22-meter ring rolling mill cylinder represents a "breakthrough in the limits of a single product," then the "composite cylinder + system integration" of the 15-meter project signifies the maturity of Hengli's "full-chain service capabilities." Today, relying on its national-level enterprise technology center platform, over 1200 patents, and nearly one billion yuan in annual R&D investment, Hengli has not only achieved independent manufacturing of the "world's largest hydraulic cylinder," but has also built a complete solution capability from core components to intelligent control systems. This strength is both a result of chance and an inevitable outcome, and a superior result of systematic innovation.

These two benchmark projects, one setting a new global standard for size and the other establishing a benchmark for complete self-reliance and controllability, together demonstrate that Chinese hydraulic companies have the capability to break the import monopoly and achieve independent breakthroughs. Furthermore, they have taken the lead in the global field of large-scale forging power technology, injecting strong and sustainable momentum into the self-reliance process of China's high-end equipment manufacturing.